GAMELAN WITHOUT FORGES MORE STABLE COMPARED TO FORGED GAMELAN

02/07/2020 Views : 331

I KETUT GEDE SUGITA

The main

process in gamelan production is the casting process. The casting process

traditionally uses open molding. The weakness of this method is the amount of porosity

that occurs in castings. Craftsmen usually do the advanced process that is the

forging process. The material is forged repeatedly so that it becomes solid and

porosity shrinks. Improvements to the components and casting process can reduce

porosity, which results in better acoustic properties of the gamelan.

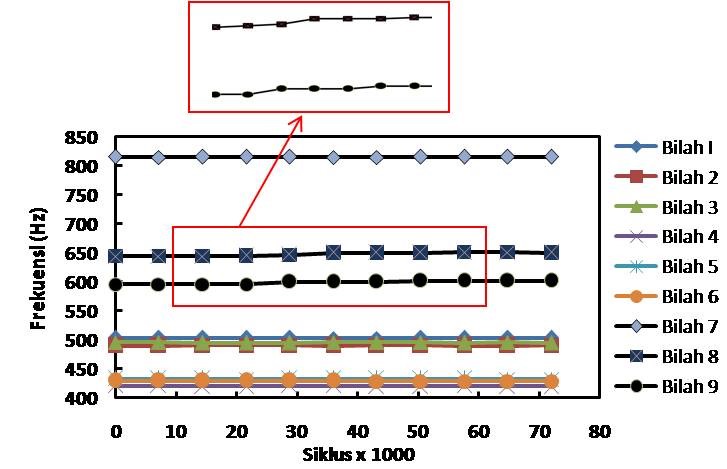

Javanese or Balinese gamelan music players mostly play gamelan by hitting, repetitively according to the music being played. Figure 1 shows the sound resistance testing of casting bronze gamelan blades without forging and bronze gamelan with forging. Sound resistance is the gamelan's ability to receive repetitive loads (under plastic load) without changing its frequency

For frequency shift investigation, the original fundamental frequency of each alloy is measured and then each alloy is subjected to impact load by hitting them such as when they are played in daily use. The total number of cycles (hits) experienced by each alloy is 72,000. Finally the resulting fundamental frequency is measured and compared to the previous (before hitting) conditions. The frequencies were measured after a certain interval numbers of hit until total of 72,000 hits.

• Blades 1 - 6, Gamelan

without Forging

• blades 7 - 9, forged gamelan

It can be

seen from Fig. 1 that most of the frequencies of the bars (Bilah # 1- 6) measured

after a certain number of cycles remain unchanged (constant). No frequency

shift indicates that the bar will not detune (lost its tune) easily so that a

good sound quality can be maintained. An interesting phenomenon was observed

for bronze alloys that experienced forging process after casting and cutting.

These alloys easily change their frequencies, and in this study frequency

shifts up to 6 Hz were observed. It seems that the forging process that is

currently applied for these alloys tends to deteriorate their acoustics

properties as indicated by the frequency shift.

Frequency changes are caused by the release of residual

stress due to forging loads

It can be

seen from Fig. 1 that most of the frequencies of the bars (Bilah # 1- 6) measured

after a certain number of cycles remain unchanged (constant). No frequency

shift indicates that the bar will not detune (lost its tune) easily so that a

good sound quality can be maintained. An interesting phenomenon was observed

for bronze alloys that experienced forging process after casting and cutting.

These alloys easily change their frequencies, and in this study frequency

shifts up to 6 Hz were observed. It seems that the forging process that is

currently applied for these alloys tends to deteriorate their acoustics

properties as indicated by the frequency shift.

Frequency changes are caused by the release of residual

stress due to forging loads